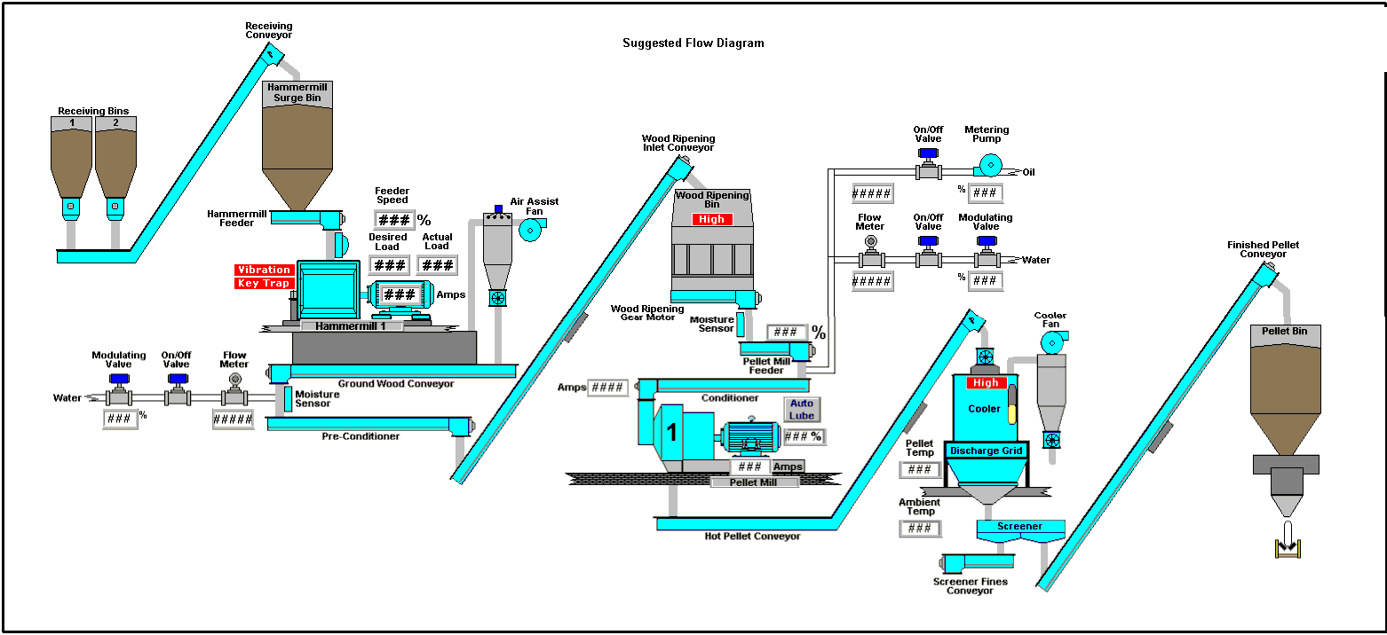

Wood Pelleting Process

- Dry wood (8-10%) to the hammermill

- Feed stock size not to exceed 1-3/16”x1-3/16”x3/8”

- Conditioner after hammermill for moisture addition

- Retention bin with at least 20 minute capacity

- Moisture meter after retention bin

- VFD Feeder for PM Conditioner

- Conditioner

- Pellet Mill

- Cooler

- Screener

Horizontal Flow

Water addition after hammermill

- Add water so it can soak

- Create homogeneous moisture in each particle, especially after dryer

- Controlled flow from hammermill

- Conditioner model LL or LT for larger capacities

Moisture measured at inlet of ripening bin with online moisture analyzer

Stable moisture for stable process conditions

- Optimizes pellet quality

- Minimizes energy usage

- Provides longer die and roller life

Ripening at retention vessel

Mixing bin or vertical bin:

• Variations in moisture

• Variations in product type

Vertical bin:

- First in first out

- Larger volume, longer retention time

Mixing bin:

- Homogenizes the raw material

- Limited retention time

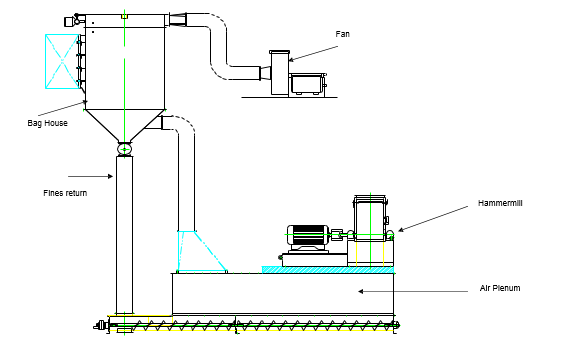

Hammermills

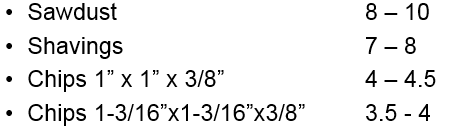

- When selecting a hammermill for wood grinding it is important to use the correct constant based on the size of incoming material.

Grinding Constants

Hard & soft wood 8-12% moisture

Hammermill screens

PELLETS

¼”– 5/16”

SCREEN HOLE

16/64th – 20/64th

Ancillary equipment for hammermill

VFD Screw Feeder

Air Siphon Feeder

Air Assist package Alt II style III filter

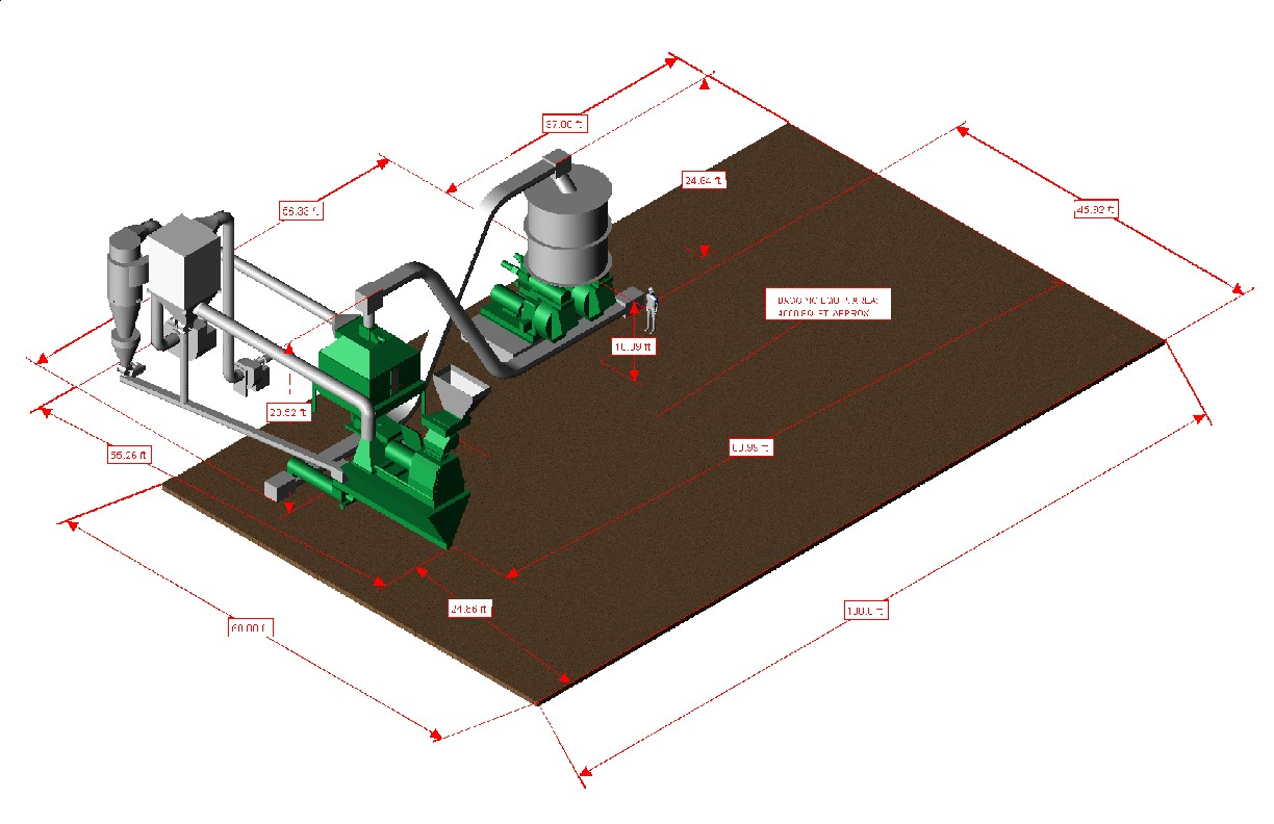

Pelleting

pellet mills

- with 400 Hp.

- Capacity 4 – 5 t/h

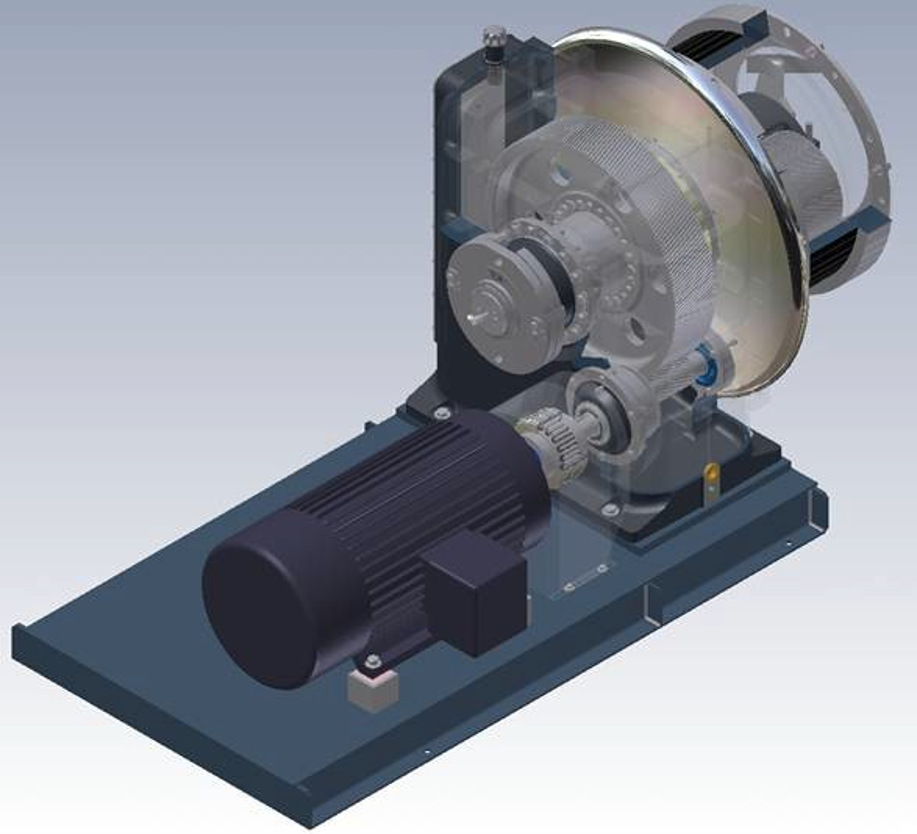

Heavy Duty Low Speed Gearing

Gear Box

Shear Pin Protection

Standard features on wood pellet mills

- Closed End Corrugated Roller Assemblies with Spherical Bearings.

- Bear Claw Die Clamp

- Doors set-up with ability to use four knife post

– If pellet length is an issue, cutter bars can be added

- Air Actuated Feed Chute

- Forced Lubrication

- Auto Lube system

- 18INF6.5 Conditioner at 300 rpm

Technical details

Grease lubrication for rollers

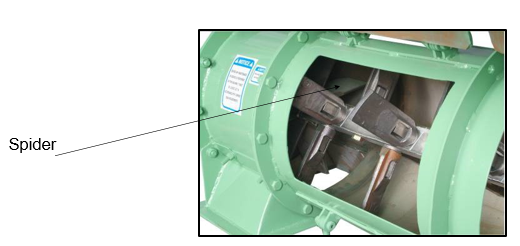

Conditioner model 18INF6.5

- Shaft speed 300 rpm optimum speed giving minimum pulsing

- Spider fitted at conditioner outlet to reduce pulsing

Infusion Conditioner

- Right Hand Access Doors

- Inlet Magnet & Housing for Conditioner

- Short Retention Inlet Drive with stainless steel clad shaft

- Shaft Mounted Gear Reducer, 7.5 Hp. 300 RPM, shaft speed

- Base Frame for 7930 Pellet Mill

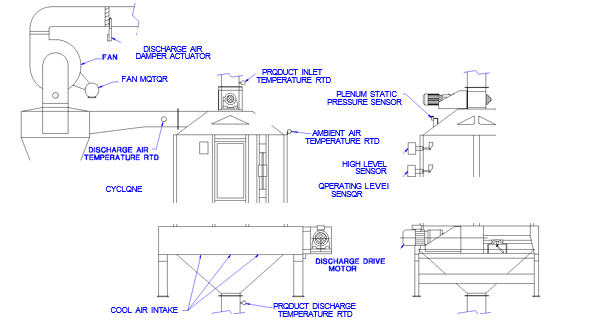

COOLING WOOD PELLETS

Remove heat and moisture to acquire:

- Dry pellets with hardness and strength

this provides:

- Transport ability

- Storage ability

hot & moist pellets 180-230°F

Pelletmill Controls

Automation is available to control all of the pelleting process.