As the mill compresses the raw material into pellets, some of the material fails to be compressed into pellets. This dust is referred to as fines. Fines are particles of material that failed to bind to the pellet during pellet formation. This could be due to a lack of pressure in the pellet mill or a lack of binding. If the pellets produced are not mechanically strong, as the pellets move and rub against other pellets and surface particles break away from the pellet. Again these particles are described as fines. So the performance of the pellet mill and the quality of the finished pellets affect the percentage of fines.

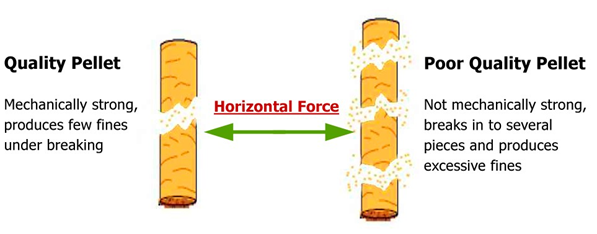

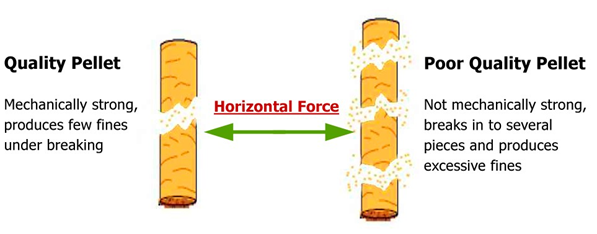

Pellets are display strength under vertical pressure but break fairly easily under horizontal pressure. Pellet breaking is not that important, but how the pellet breaks is. When horizontal pressure is applied to quality pellets the pellet should break cleanly. A poor quality pellet however, under horizontal pressure, will break into several pieces and will produce fines.

The importance of the quantity of fines depends on the pellets’ target market. Fines can interfere with the pellet feed system for the pellet stove/boiler; this is more of an issue with small residential units. Also, pellet stoves and boilers have the feed rate and fan speed set for pellet combustions. This system becomes inaccurate in the presence of fines because fines burn faster than pellets. In some pellet burners this can cause the ash to melt and sinter. For premium wood pellets, the target is for fines to be less than 1 percent by weight. The European CEN standard has specifications for the maximum allowance of fines, and in many cases the percentage of fines must be stated when sold. Pellets in bags tend to have fewer fines than those sold in bulk sacks. Pellets that are stored in silos generally have more fines on delivery.

Graded sieving

After production pellets can be run over a vibrating screen to remove fines. However, if the pellet mill is setup properly and the material is properly compressed, this may not be required. However the mechanical strength of pellets should be carefully tended to, as this will reduce fines after production.