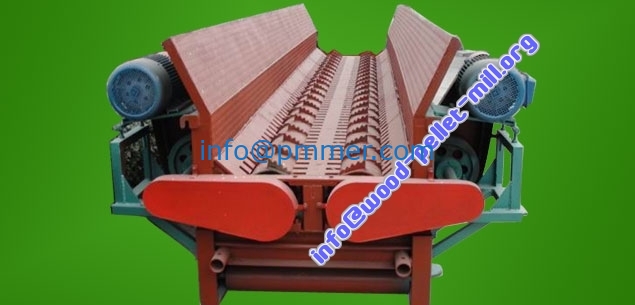

Wood peeling machine is the preferred equipment to replace hand peeling. It can be used to peel kinds of woods &widely adopted by paper pulp factory,paper mill and other factories.Raw materials for these machine are raw woods of which diameter within 50 to 300mm.

Features of Wood Peeling Machine

* The adoption of four-side-edge shearing blade prolongs the service life of blade.

* Chipper disc pressure regulating is controlled by hydraulic pressure.

* Feeding system adopts step-less speed change which enables the machine to have good peeling effects on hard peeling woods, such as frozen woods, curved timber, eucalyptus, oak woods, elm, etc.

* Raw woods peeling rate is more than 95%.

* Reasonable structure and high efficiency.

* Easy to operate, simple to maintenance.

* Safe and reliable, long service life.

* Small injury to woods, low cost, and low failure rate.

* Automatic production largely saved man power.

Application Scope of Wood Peeling Machine

Wood peeling machine can be employed to peel newly cut soft woods, part broad-leaved woods and part frozen woods, dry woods.

Working Principle of Wood Peeling Machine

First put raw woods, tree branches and other woods into drum, then close feed deflecter and start the machine, it will running in the clockwise direction. Woods in the drum will rotate along with the machine to make bark to be peeled by blades. Turn off the machine 15 minutes later, open discharge deflecter, start the machine and make it running in the anticlockwise direction, peeled woods will automatically discharged from the drum.

Technological Parameter of Wood Peeling Machine

|

Model

|

6 meter

|

12 meter

|

16 meter

|

20 meter

|

|

Double Roller

|

Ф325mm

|

Ф325mm

|

Ф325mm

|

Ф325mm

|

|

Rotor Speed

|

90r/min

|

90r/min

|

90r/min

|

90r/min

|

|

Capacity

|

6-8T/H

|

12T/H

|

15T/H

|

20T/H

|

|

Peeling Rate

|

>90%

|

>85%

|

>85%

|

>85%

|

|

Motor Power

|

7.5*2kw

|

7.5*4kw

|

15*4kw

|

18.5*4kw

|

|

Weight

|

3.2t

|

7t

|

12t

|

14.8t

|

|

Size

|

6.6*155*1.4m

|

12*1.5*1.8m

|

16.5*1.6*2m

|

20*1.6*2.2m

|