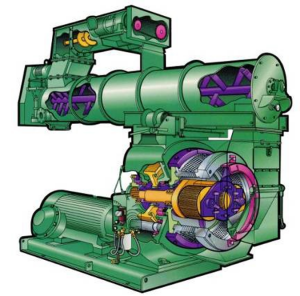

The hammer mill and pellet mill utilize a number of bearings which reach high temperatures during operation. Frequent checks of these bearings are required to maintain equipment performance and life. Maintenance of pellet mill & hammer mill is very important to prolong the life of equipment.

Checking that the hammer mill and pellet mill operate with the least resistance will keep energy demand to a minimum. For example check that there is no build up of material causing extra friction around the pellet mill die and rollers. Without these checks energy will be wasted on the extra friction placed on the die and rollers.

At the end of production it is important to clean the pellet mill die so production can be easily restarted. If raw material is left in the die, as the die cools the material inside the die will also cool allowing the lignin to set. Once this has occurred it will be very hard to start production again and may require the die to be drilled out. The extent of the problem depends on the material processed, the die type and the metal.

If the raw material was a low-density oily material, die cleaning is not required. However in most cases with wood and other biomass pellets this material must be removed from the die to make production start-up easier. At the end of production, a low-density oily material should be processed through the pellet mill. This low- density oily material will not set as hard as the raw material, enabling easier start-up. Possible materials include wheat bran, flour, corn or barley mixed with vegetable oil.

As described earlier there are different types of dies. For instance, carbon steel dies have corrosion issues. Because of this, the hole finish is not as smooth as in other dies. If the raw material is left in a carbon steel die to cool, the moisture released during cooling will form corrosion around the inside of the die hole and lock the material in the die, requiring drilling. In contrast high chrome dies have a much smoother hole finish and do not have corrosion issues. Therefore the material does not form such a tight bond, making production start-up easier. However it is generally advisable, no matter what the die metal or finish, to always leave a loose oily mix in the pellet mill at the end of production.

Troubleshooting

Mill won’t start

| Possible causes | Remedy |

| Improper wiring | Check system to ensure that the motor is wired correctly. |

| Seized rollers | Disconnect power source.Check for debris in front of the rollers, and clear if present.

Reconnect power and restart mill after debris is removed. |

Pellet won’t form

| Possible causes | Remedy |

| Improper material input | Check input material for proper 10 to 15 percent moisture content.Check input material for lignin content. If the material is not organic in nature, it will not contain lignin and will not palletize. |

Seized die

| Possible causes | Remedy |

| Material is too dry and/or die is not properly lubricated. | Clean the die by soaking it in glycerin. The length of time necessary to soak the die depends on the material in the die; woody material may require up to 24 hours.Drill out individual borings with a hand drill. |

Pellets are too dry

| Possible causes | Remedy |

| Lack of moisture in feedstock | Add water or moist material prior to pelletization. |

Pellets are too wet

| Possible causes | Remedy |

| Too much moisture in the feedstock | Dry material or mix with a lower moisture content. |

Lackluster pellets

| Possible causes | Remedy |

| Low pellet temperature | Allow mill to warm up. |

| Wet feedstock | (same as above) |

| Dry feedstock | (same as above) |

Non-durable pellets

| Possible causes | Remedy |

| Pellets improperly cooled | Cool pellets on a screen or conveyor. |

| Low pellet temperature | Allow mill to warm up. |

Excessive wearing of die and/or rollers

| Possible causes | Remedy |

| Foreign matter in feedstock | Use clean biomass material on subsequent runs. |

| Improperly prepared material | Reduce size of biomass prior to processing by changing the screen size in the hammermill. |